One platform, many options: using Bauerfeind’s BODYTRONIC ID:CAM system solution, medical retailers can now have digitally modeled orthotic blanks manufactured as a 3D print – carried out centrally by Bauerfeind or using an in-house solution. The fourth dimension following scanning, designing, and manufacturing refers to the comprehensive service which includes an intensive four weeks of onboarding. The system update is complemented by a modern user interface and a treatment configurator.

The revised BODYTRONIC ID:CAM system solution includes an open scanning interface for medical retailers, different digital modeling tools, comprehensive service, and 3D print or milling manufacturing options. Users can switch between central or in-house manufacturing at any time.

“The BODYTRONIC ID:CAM and 3D print leasing model allow orthotists a way into digital foot orthosis manufacturing without a financial risk,” explains Martin Hepper, Head of the Foot Orthopedics Divisional Organization at Bauerfeind. “Companies will benefit from maximum flexibility, quick availability, sustainable production with little waste, and close support during manufacture of the first products.”

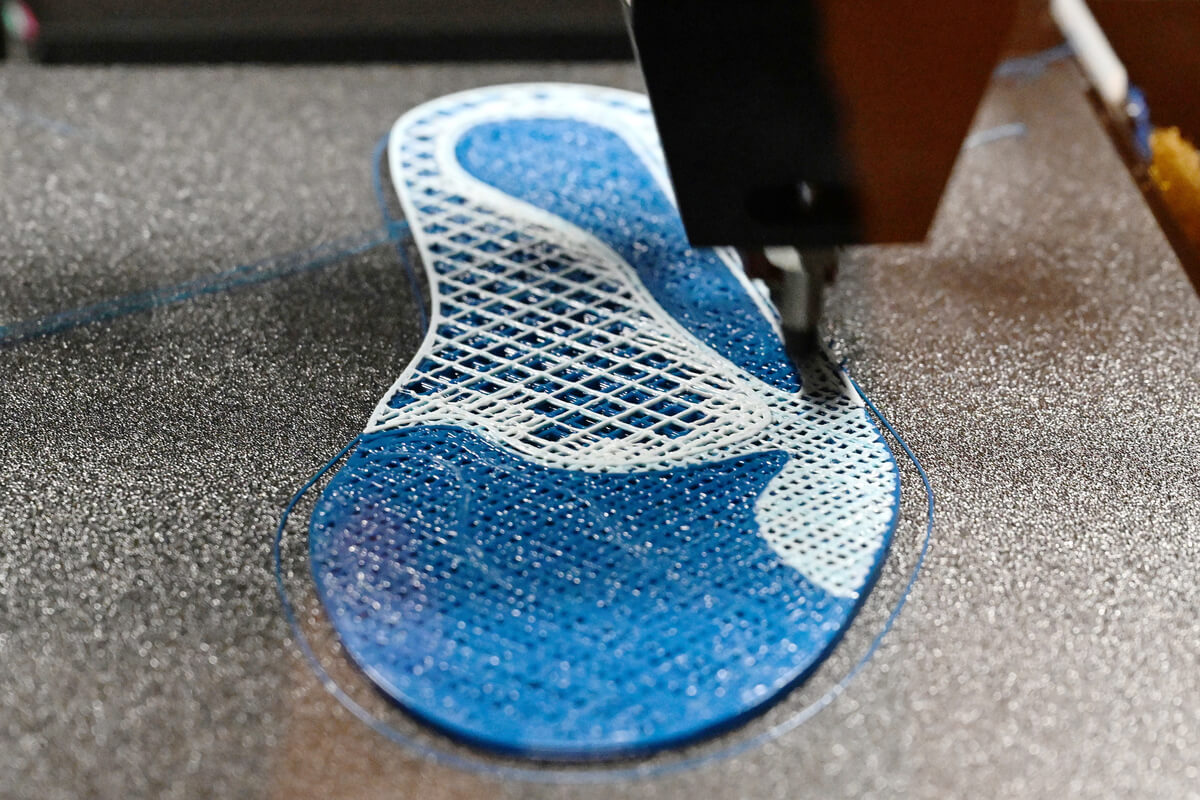

3D print provided by Bauerfeind: different densities in one foot orthosis

Printing is performed using FGF 3D printing technology (Fused Granulate Fabrication), meaning the printer processes plastic granulates (pellets), developing the orthotic blanks layer by layer. The material can be printed in different structures – either in a particularly soft cushioning wave shape (gyroid) or in a supporting grid pattern (rectilinear). In this way, stability, flexibility, and the cushioning properties of the orthotic blanks can be targeted. Orthotic blanks with one, two, or three layers are possible where the materials can be combined freely. Furthermore, the density within the individual models can be adjusted, meaning defined functional zones are created in as little as one printing process.

When using the 3D print leasing model, medical retailers can choose between a single or double unit and adjust their production capacity as required. In addition to the hardware, the monthly leasing fee also includes maintenance, spare parts, and technical support. Consumables are invoiced based on pellets, which creates full transparency and costs that can be planned.

Treatment configurator: the system solution is becoming more medical

In addition to integrating 3D print, the BODYTRONIC ID:CAM update also includes a revised user interface and the new treatment configurator. Once the foot scan data has been loaded and the insole has been specified, the user decides whether the foot orthosis will be created independently using the 3D data mode or if the treatment mode will come into play: this mode will offer indication-specific predesigns (normal foot, skew/arch decreased/splay foot, and high-arched foot with valgus or varus misalignment) as well as a flat design. These predesigns can be used as a basis for modeling, and are suitable for foot orthoses both for children and adults.

A comprehensive, future-proof solution

BODYTRONIC ID:CAM is free to use. There are no licensing, service, or update fees. The user merely requires online access. This provides medical retailers with a system solution that digitally links all production steps – from scanning and designing to manufacturing the milled or printed orthotic blanks. This makes it economical, sustainable, and future-proof.